Leading the way in

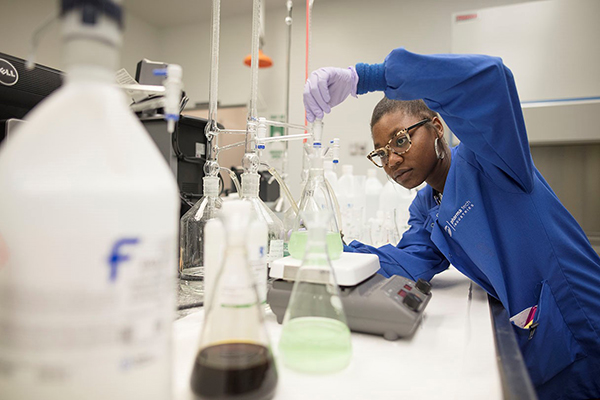

POWDER EXPERTISE AND INNOVATION

From formulation development, blending and manufacturing to packaging and serialization, PTI offers a range of solutions to meet your individual specifications and your market’s desires. Our facilities are FDA-registered, NSF-certified, climate controlled and operated under cGMP.

Put the power of PTI to work for

your brands.

Ensures optimized efficiency, from development through commercialization

Ensures successful project execution throughout the life of your project

INNOVATION

- Complex blending

- Convenience dosing

- Capsule filling

- Micro-dosing capsule filling

- Tableting/bilayer tableting

- Effervescent

- Commercial Packaging

- Bottle and cap manufacturing

- Sachets

- Stick packs

- Zippered pouches

- Ribbon and blister packs

- Bulk packs

- Medical devices

- Microencapsulation techniques

- Powder inhalation technologies

- Taste masking

- Serialization with full traceability

- Medical device

- Containment

DEVELOPMENT

COMPREHENSIVE DEPTH AND BREADTH OF DEVELOPMENT AND ANALYTICAL SERVICES TO SUPPORT RAPID PRODUCT DEVELOPMENT

Our offerings provide a wide range of benefits that can help ensure your project success.

Our capabilities include:

- Formulation and engineering expertise to provide right first-time solutions

- Fully functioning (qualified and staffed) GMP analytical/microbiology- analytical method development and finished product testing per USP: raw material, in-process and finished product testing

- Tailored stability programs across multiple dosage forms

- Operational excellence – ensuring optimized efficiency, development through to commercialization

- Standard and customized services – placebos, containment, low volume to multi ton manufacturing, early inception through to commercialization

MICROENCAPSULATION

PUSHING THE LIMITS OF POWDER EXCELLENCE THROUGH MICROENCAPSULATION

Microencapsulation is the process of forming a shell around a microscopic and infusing it into products to make everyday life better.

The benefits of microencapsulation:

- Taste masking – pediatrics

- Targeted release and delayed release

- Increased stability

SPECIALTY FILLING AND CONTAINMENT

Our state-of-the-art production rooms are designed for filling and packaging of specialty products, even those requiring containment. In addition to maintaining a clean air environment, temperatures are kept under 25°C and relative humidity below 30%. Our equipment includes stick pack pharma machines, capsule filling machines, a complete bottling line, tablet presses as well as packaging lines. Blending capabilities are in place as well. Storage for finished product is available in our warehouse at controlled temperature. We also provide raw material storage in a dedicated cold room, keeping a consistent temperature of between 2°C- 8°C. An onsite laboratory ensures industry quality standards.